laminating glass autoclave|Glass Laminating Autoclaves : specialty store CompuDAS offers Control, Monitoring and Data Acquisition Systems designed for Glass Laminating Ovens and AutoClaves Control Systems. Laminated, or safety, glass is the standard in many modern uses of glass, from automotive to architectural applications. Produced by bonding layers annealed or tempered glass with a plastic interlayer (often either polyvinyl butyryl or . The Genesis™ container systems are designed to achieve and maintain the sterility of your surgical instruments. We offer a variety of sterilization containers, baskets, dividers, cases, .

{plog:ftitle_list}

Autoclave repair services from All States M.E.D. restore your autoclave's performance. We perform full restorations, preventive maintenance, and more.To insure the health and safety of personnel using the autoclave, it is important for each .

ASC's GLS glass laminating autoclaves are designed with unequaled temperature and flow uniformity to ensure even heating and cooling of your glass load. Each autoclave utilizes our .Glass Laminating Autoclave Systems. The Econoclave GLS autoclave with our . When we look at glass lamination, there are 3 basic systems: Nip roller system, Vacuum bag system and Autoclave free system. . PVB trimming Benteler — automatic PVB lay up Bovone — Exit laminating line Benteler — IR heating oven Scholz autoclave Bovone — laminating line scheme Glaston — Laminating line scheme.CompuDAS offers Control, Monitoring and Data Acquisition Systems designed for Glass Laminating Ovens and AutoClaves Control Systems. Laminated, or safety, glass is the standard in many modern uses of glass, from automotive to architectural applications. Produced by bonding layers annealed or tempered glass with a plastic interlayer (often either polyvinyl butyryl or .

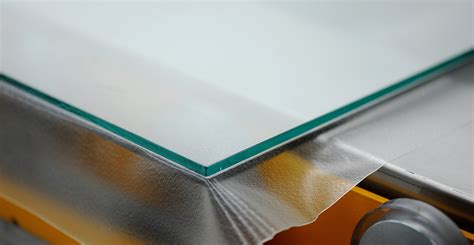

Laminated glass is typically made via an assembly line process that is followed by controlled exposure to heat and pressure in an autoclave. Curved laminates are assembled and then encased in vacuum bagging prior to autoclaving. The process for making cast-in-place resin laminates varies based on the resin. For instance, a

COMPACT - the most cost-effective type of pre-lamination for a small volume of laminated glass. COMFORT - a convenient and ergonomic, semi-automatic high-speed laminating system for customers with a wide variety of products and a large number of shapes. The line is designed for medium to high production volumes.Each autoclave utilizes our proprietary H-Slot™ flow system to create a uniform flow front from the front to the rear of the autoclave. Shorter cycle times. The glass laminating GLS Econoclave comes standard with an enhanced air circulation system that delivers, on average, 50% more flow to your laminated load than competitive autoclaves. As .Handong is an industry-leading glass processing machinery manufacturer with rich experience in glass processing and laminated glass production industry. We are committed to producing the state-of-the-art laminated glass production line and glass processing plants to our customer, including glass washing machine, heat soak furnace, glass loading .Glass Laminating Autoclave is widely used for the production of diverse laminated safety glass from small car windshields to large architectural laminated glass. We had been providing standard or custom glass laminating machines to meet your specific glass laminating process with automatic controlled pressure and temperature. The innovative and .

Standard Laminated Glass Production Line. After passing by the glass washing and drying machine, transition conveyor, double-station glass combining machine and infrared roller pressing machine in a horizontal way, the glass is processed as semi-finished laminated glass, and then finished glass is processed by the autoclave. See More +We manufacture glass laminating autoclaves in flat-sided workspace designs for maximizing load capacity. Our proprietary blower motor design is ideal for high temperature operations. A cooling system is used to limit motor capsule temperature. Operators can easily access the motor by removing the water-cooling supply and return lines of the .2.2 Laminated glass with fire resistant properties: Laminated glass which does not achieve its fire resistance by means of interlayers which react to high temperatures. 2.3 Fire resistant laminated glass: Laminated glass where at least one interlayer reacts to high temperature to give the product its fire resistance 2.4 Laminated safety glass . Architectural Glass Laminating Guide - Part 6. By Luc Moeyersons . To laminate one needs temperature, pressure and time. If the available pressure is low (lower than 1 bar — vacuum inside of the bag and ambient pressure outside), time can be used to compensate the lack of higher pressure.

abdominal tear orthopedic test

How is quality of the PVB laminated glass made by autoclave-free glass laminating machine. With more and more factories using non autoclave glass laminating machine to produce PVB laminated glass, PVB laminated glass produced by non autoclave system is more and more applied to various fields . HHH Equipment Resources offers a variety of glass laminating systems including autoclaves, production lines, laminating ovens and more. To learn more about selecting the right laminating equipment for your lineup, contact the expert HHH team. Related Equipment Spotlight. MPT GLASS MACHINERY present you the final stage on processing laminated glass. After we go through the combining (glasses+PVB films), the combined glass will.

Figure 5: A typical vacuum oven lamination program for EVA lamination. EVA is ideally suited for autoclave-free vacuum oven manufacturing. It is often the interlayer and method of choice when complex laminates with structured and/or curved glass and/or inserts need to be processed due to its good flow properties.Autoclave is the key equipment of laminated glass production, firmly will the laminated glass hold together through heating, cooling, . Compare this product Remove from comparison tool process autoclave max. 400 °CGlass laminating> Glass Machinery> Glass Machinery General> Glass Tempering - Laminating> Machinery SKU: N/A. The Press non-autoclave laminating machine offers fast lamination of PVB, SGP, and EVA films. Description Description.

7.4. Risk of volatiles evaporation & autoclave fires The plasticizer evaporates during the autoclave cycle. Plasticizer condenses in the insulation, forming a good fuel. (see also “Architectural Glass – Laminating Guide part 5 chapter K – Autoclave cleaning/purging cycle) Dowanol® TPM. 7.5. The ideal “practical” autoclave cycle. 7.6.

Jordon Glass Machinery Laminating Machines are professional glass laminating machines used without an autoclave system. The JG series can laminate EVA, SGP and PVB. . Press Non-Autoclave Laminating Machine. 0 out of 5 (0) The Press non-autoclave laminating machine offers fast lamination of PVB, SGP, and EVA films. SKU: N/A. View Product. QX .In the manufacturing process, the assembly of float glass and PVB are laminated together and then placed in an autoclave. A typical autoclave lamination cycle ramps pressure to 180 psi (12.4 bar) and temperature to 280 °F (137 °C).Thompson Innovative Glass produces laminated glass using advanced lamination and autoclave technology. Beyond strength and safety, laminated glass also offers excellent sound absorption and ultraviolet filtration. Up to 99% UV radiation can be blocked to help protect against fading of interior objects such as artwork and furniture fabrics.Laminated Glass. NWI is proud to offer custom sizing and a large in-house inventory of laminated glass available for immediate delivery. Northwestern Industries makes laminated glass using an automatic production line and a hot-air autoclave. We are capable of handling sheets as large as 84″ x 174″ that range from 9/64″ to 2″ thick.

Architectural laminated glass – Autoclave . Architectural laminated glass – Non-autoclave Process; Courtesy of HOAF . Architectural laminated glass – Most common laminating defects and origin . Architectural laminated glass – Photovoltaic Lamination process (Co-author Vittore de Leonibus – Teknisolar) Courtesy of TeknisolarGlass Laminating Autoclaves. ASC's Econoclave GLS models and CPC control systems are used by the glass industry to bond and cure laminated glass for architectural, automotive, and ballistic applications. Learn More. Ballistic Armor Autoclave Systems.The lamination process involves subjecting the glass and interlayer to controlled heat and rolled pressure at specific speeds to ensure a strong bond. Once the unit is complete, it is transferred to an autoclave, where high pressure and heat are applied to further enhance the bond between the glass and the interlayer (PVB or Inoplast).

Glass Lamination

Glass Laminating Autoclaves

ac tear test

Autoclave Engineers was the first to develop magnetically coupled mixing technology for use in high-pressure chemical research and development. The new i2MAG075 Series MagneDrive .

laminating glass autoclave|Glass Laminating Autoclaves